Machining very large cast parts such as turbine housings is a real challenge. Highly fluctuating profile measurements, major differences in diameter or considerable imbalances are just a few of the parameters which demonstrate that Walter special tools are the right tools for the job.?

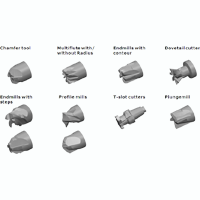

We develop special side and face mills for our customers, with diameters of over 2 metres. The uniqueness of the machining task is matched by the uniqueness of the special tool. For example, the degree of accuracy required for the profiles of the turbine blades and turbine shafts used in steam turbines is extremely high. We will provide you with insert finishing end mills for finishing blade roots and attachment grooves in turbine shafts: with these mills, you will be able to achieve a degree of profile accuracy of +/- 0.01 mm. The Walter Prototyp ConeFit™ system is one of the most successful modular tooling systems for milling.